The reason for an SSCC

When confronted with the topic of SSCCs and the unique identification of shipping units for the first time, the question of why this approach is necessary (and of course if the financial expense entailed is justified) will often arise.

On closer inspection one can recognise a number of reasons, why a company may benefit from the unique identification of its shipping units. In order to allow for an effective quality management, each shipment must be uniquely identifiable along the supply chain. Thereby, the affected parties such as consignor, consignee, carrier, freight forwarder, etc. shall reference a shipment using the same unique number.

The numbering system used should ideally:

A) prevent duplicates and be unique to every involved party.

Global uniqueness cannot be guaranteed with self-assigned numbers generated by, e.g. the consignor or the carrier.

B) be readable and processable by a machine.

This implies that the numbers shall be represented as bar codes and shall also be integrated in existing EDI processes (e.g. notification about an upcoming shipment using a despatch advice message).

Unique identification of shipping units will allow end-to-end control of goods movement. Machine processing of shipment data reduces staff costs and significantly increases the reliability of the recorded data (e.g. compared to paper-based delivery slips).

Another reason for the introduction of a unique shipment tracking are legal requirements, e.g. the tracing of food or pharmaceutical deliveries.

Learn how to unlock the potential of EDI with ERP integration

SSCC characteristics

The length of an SSCC is 18 characters and it is based the GS1 Company Prefix.

The guaranteed global uniqueness allows participating companies to use the SSCC for shipping unit identification without the risk of incorrect identification caused by duplicate codes.

The consignor generates the SSCC number, comprising a number and a bar code on a label, and attaches the label to the shipping units. The participating parties in the downstream process (e.g. carrier, freight forwarder, etc.) may scan and store the number. Furthermore, the SSCCs are included in EDI messages, which accompany the shipment, e.g. despatch advice messages. Using the scanned information together with the EDI messages the physically received goods (according to the scan) may be compared with the expected goods (according to the EDI message).

The combination of electronic transmission of SSCCs together with SSCC labels creates a traceable end-to-end process.

SSCC structure

As with all numbers in the GS1 numbering system, the SSCC is also based on the GS1 Company Prefix, which a company must aquire first. The GS1 Company Prefix may then be used to generate the different GS1 number types, for instance Global Location Numbers – GLN. In brief: a GLN is a globally unique and non-overlapping number to uniquely identify a company. Since the SSCC is also based on the GS1 Company Prefix, it is also globally unique and non-overlapping.

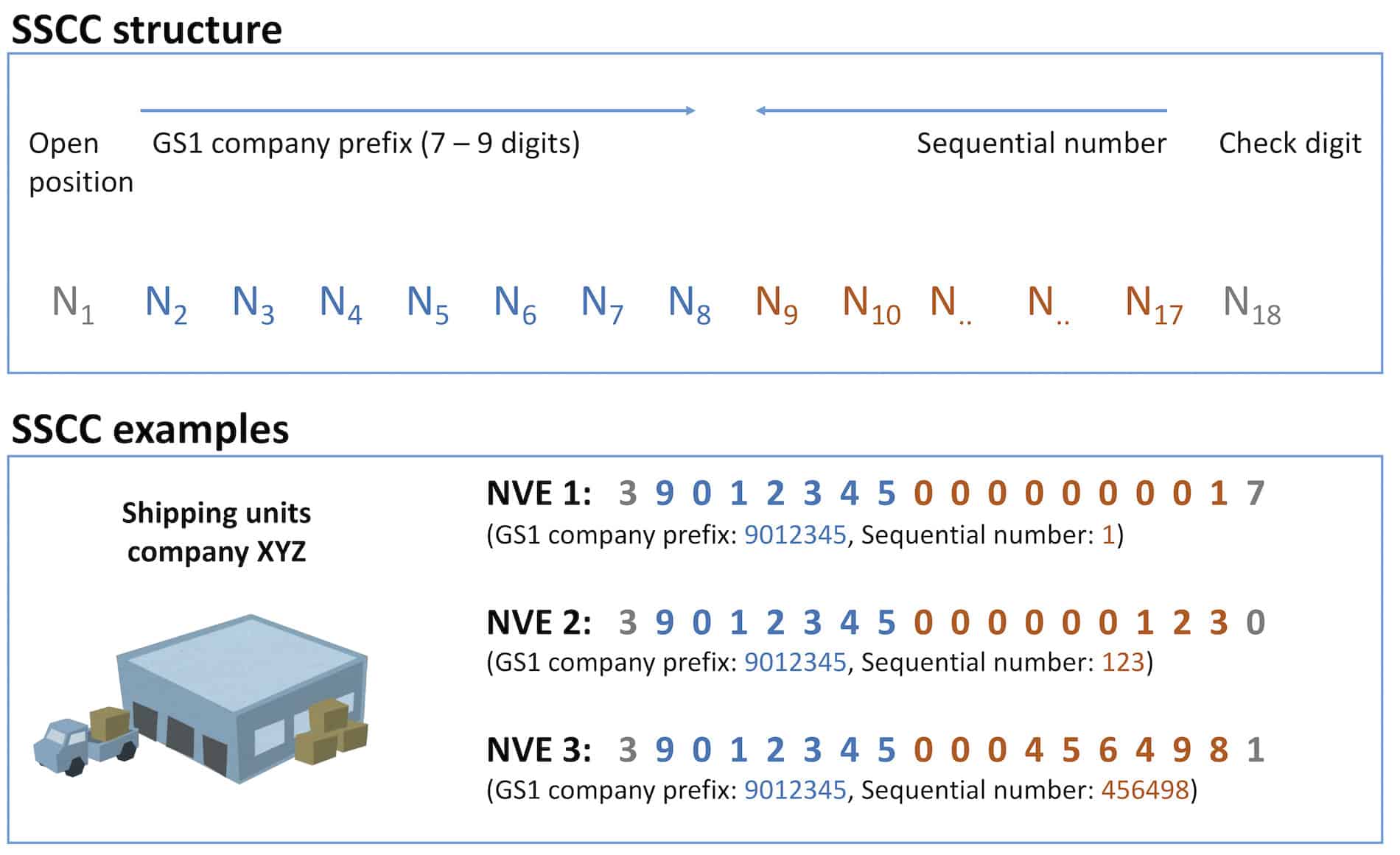

The following illustration depicts the precise structure of an SSCC.

An SSCC starts with an open position that is selected by the company itself. It is followed by the 7 to 9-digit GS1 Company Prefix, depending on the type of GS1 Company Prefix, which is being used. The length of the company prefix determines the SSCC number range. A shorter company prefix allows for more SSCC numbers.

The company prefix is followed by a sequential number, used to identify the shipping units. Although GS1 has no specific requirements, a continuous ascending numbering system starting with 1 is recommended.

Considering the open position and the length of the company prefix, the numbering ranges are as follows:

9-digit company prefix: 100 million possible SSCCs

8-digit company prefix: 1 billion possible SSCCs

7-digit company prefix: 10 billion possible SSCCs

As with all GS1 numbers, the last digit is a “check digit” calculated using the previous 17 digits.

The GEPIR services of the various national GS1 locations may be used to find the company behind a specific SSCC:

Using SSCCs

The question of which shipping unit to mark with an SSCC often arises. Depending on the application scenario, shipping units may be entire containers, pallets, packages, small parcels, etc.

GS1 in general recommends the following:

An SSCC identifies the smallest physical unit of goods and freight, that is not permanently connected to physical units and that can be individually handled by the consignor and consignee.

Example: Boxes with pencils

- One EUR-pallet is loaded with individual boxes containing pencils.

The boxes are self-contained and are not connected (e.g. not wrapped using stretch wrap). In this case each box constitutes a shipping unit and may thus be marked with an SSCC. The pencils in the box will have a GTIN, independent of the SSCC. - The boxes may be wrapped using stretch wrap to prevent them from falling apart during transport. The pallet itself (comprising the individual boxes with pencils) is also a shipping unit and will be assigned an SSCC.

- Should the pencils be packaged in small parcels (e.g. 10 pencils each) inside the box, the small parcels could also be assigned an SSCC – for example, if some of these parcels are delivered by a logistics service provider.

Service providers along the supply chain may bundle individual shipping units to create larger units (e.g. by loading the pallets into a container). This creates a new shipping unit – in this case the container. The original shipping units will, however, remain unchanged and be used down the line (when emptying the container).

The level of SSCC granularity needs to be agreed upon by the participants along the supply chain. Typically, the larger business partner (e.g. a large retailer) defines the exact process requirements and all other suppliers, logistic providers, etc. have to comply with these requirements accordingly.

An SSCC is exclusively used for the identification of a shipping unit. If the shipping unit is also a standard trading unit that is being sold (e.g. a box with pencils), then the trading unit is also assigned its own GTIN in addition to the SSCC.

You can learn more about it in our article “What is a DESADV with SSCC and Why Should I Care?”.

Assigning SSCCs

The company manufacturing or assembling the shipping unit is responsible for marking the shipping unit with an SSCC.

All other participants along the supply chain are supposed to reuse the SSCCs already attached to the shipping unit. This ensures that a shipping unit retains its original SSCC number along the way from consignor to consignee.

Marking shipping units

GS1 recommends using GS1 transport labels in order to attach SSCC numbers to shipping units. A transport label is attached to the shipping unit (e.g. pallet) and may be scanned by participating companies along the supply chain, for instance to compare the shipped goods to EDI despatch notifications.

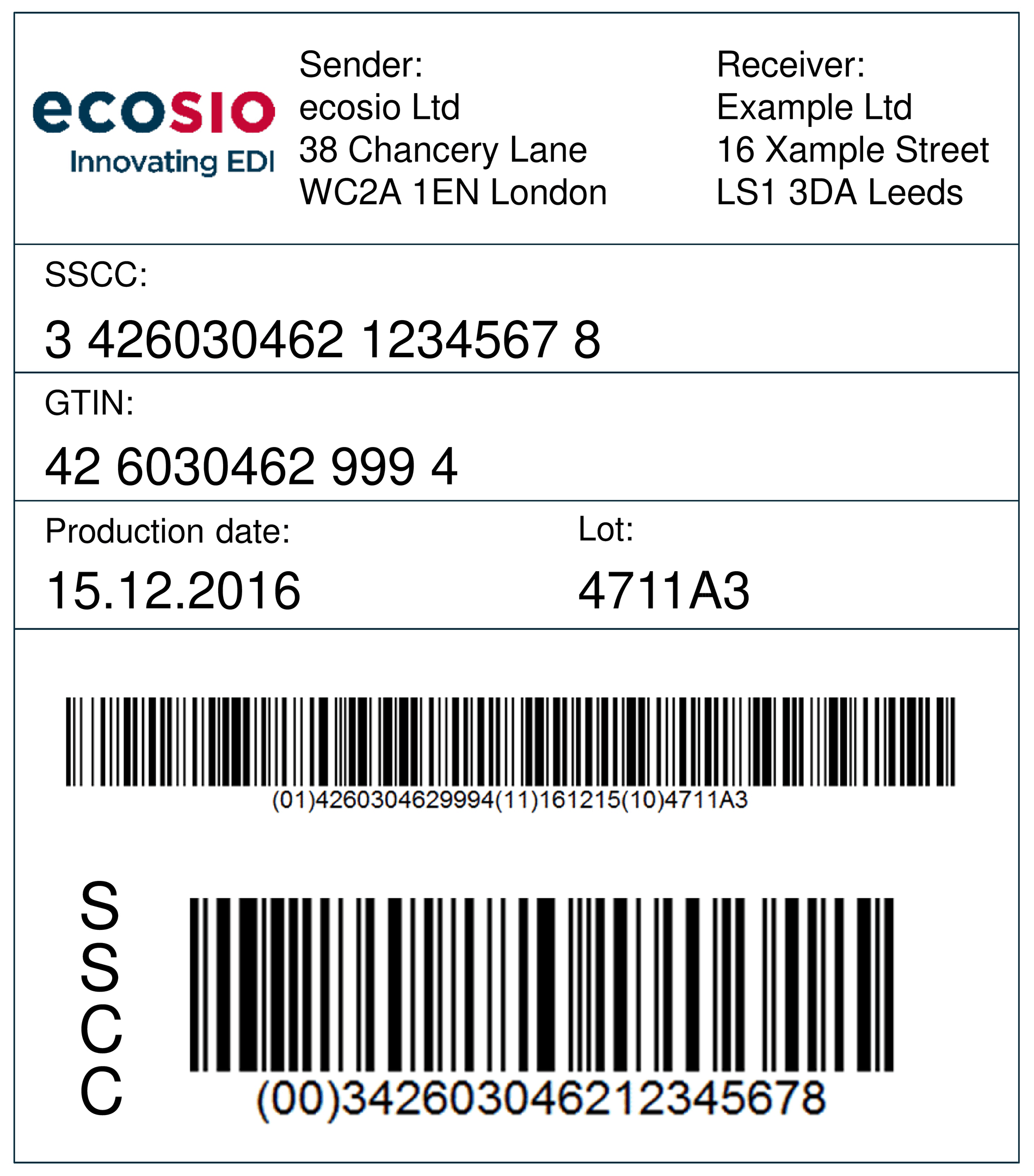

The illustration below shows a fictitious GS1 transport label of ecosio Ltd.

The core element of the transport label is the SSCC 342603046212345678, shown both as a visually readable number and as a GS1-128 bar code. GS1 specifications determine that the SSCC bar code should always be printed at the bottom of the label, as it represents the primary label information.

Additional information such as batch/lot number (4711A3), GTIN of the trading unit (4260304629994), etc. may also be shown on the label.

Introduction of SSCC processes in a company

SSCC labels may, depending on the company’s production process, be applied already at the end of production (if the production unit already constitutes a shipping unit) or later on at the loading ramp, where individual products are combined to create shipping units.

When introducing an SSCC process in a company, process and hardware adaptations are usually required, e.g. acquisition of label printers and SSCC scanners. The introduction of SSCC is often triggered by a larger business partner, which demands SSCC compliance from its suppliers. For a supplier the introduction of an SSCC process roughly implies:

- Generation of SSCC numbers. Generation can for instance occur in the ERP system.

- Transmission of an electronic despatch advice message (e.g. EDIFACT DESADV), which contains the SSCC information.

- Application of the SSCC label and shipment of the goods

Questions about SSCC or EDI?

Do you have any more questions about SSCC or EDI? Please do contact us or use our chat — we’re more than happy to help!