The logistic challenges of retailers

Before we get into looking at DESADV with SSCC in detail, it is first necessary to understand the context. The retail trade has seen substantial changes in recent years. Most small grocery stores have closed down and branches from big retailers dominate the market. The difference between these small grocery stores (also known as convenience stores) and the modern supermarkets from today is, that supermarkets offer a much larger variety of products, which suppliers need to keep restocking.

An old fashioned grocery store

For retailers however this means that the ordering and shipping of goods from the manufacturers to the branches must take place smoothly and efficiently.

Depending on the type of goods, the companies rely on a direct store delivery or warehouse delivery.

Two things are crucial when it comes to deliveries:

- The goods arrival needs to be announced on time to allow correct planning of the inbound logistics for the retailer.

- The announced delivery and the physical delivery need to be clearly assigned.

The first case scenario is supported by the DESADV EDI message type. This EDI message needs to be sent before the goods physically arrive at the warehouse, as it describes the exact structure and content of the delivery.

The second case scenario is supported with identifiers, so called SSCC numbers (Serial Shipping Container Code). This number is fitted on the delivery as a physical, machine readable sticker with a barcode and is also contained in the DESADV message.

This allows the delivery process to the warehouse as illustrated in the image below: On the left side, we can see the goods have arrived in the warehouse and are being distributed to the correct shelves. In case of a cross docking delivery, the storing is bypassed and the goods are to be loaded on another truck right away.

Inbound logistics in a warehouse

Thanks to the supplier’s prior notice, the warehouse employees can plan the shelf space and immediately know where the pallets need to go.

Furthermore the pallets are fitted with the SSCC labels, which the warehouse employees can scan by hand (see illustration below). The employees scan the SSCC numbers and compare them with the data from the DESADV that was sent earlier. This way, they can verify whether the quantity or the structure of the shipment is correct.

A hand scanner being used in a warehouse.

What becomes clear with the above description of the process, is that the cooperation of the suppliers is vital to ensure a smooth running of the logistics. The DESADV messages have to be sent electronically and long enough before the arrival of the goods, and they must contain the SSCC numbers, which are also mentioned in the label of the shipped goods.

SSCC number example

SSCC numbers are used for the clear identification of shipping units.

SSCC numbers are based on a GS1 company prefix, just like most GS1 identification numbers. Other GS1 identification numbers include for instance GLNs and GTINs. A GLN – Global Location Number is a global, unequivocal and non-overlapping identification for a specific business. GTINs (Global Trade Item Number) are used to clearly identify products.

SSCCs have 18 digits and are set up as follows:

- 1 reserve digit

- 7 – 9 digits of the GS1 company prefix

- A consecutive number for the shipping unit. The allowed length depends on the length of the GS1 company prefix.

- A verification number.

Let’s use the ecosio InterCom GmbH GLN 4260304620007 as an example to create a SSCC number. The GS1 company prefix is 426030462:

- Reserve number:

3 - GS1 company prefix:

426030462 - Consecutive number for the shipping unit:

1234567 - Verification number:

8

We now have the SSCC 342603046212345678. This number can be used for the clear identification of the shipping unit. Since it is built using the GS1 company prefix, it is guaranteed that this SSCC will not be used by another company.

Here you can find out more about creating a SSCC number.

SSCC transport label

In order to easily and efficiently process the SSCC number in the logistic chain, it is necessary to display it as a machine readable barcode. The barcode can be captured by an optical reader, thus allowing a complete delivery to be unloaded in the warehouse, without anyone having to manually type any data.

This is exactly what the GS1 transport label is for. Not only does it contain information that the human eye can read, but also machine readable data contained in the barcode. The following picture illustrates the set up of a GS1 transport label:

Set up of a GS1 Transport Label

The label is composed of a header segment, which contains free formatted information about the sender and receiver. The middle segment contains information in clear text, whose size can vary, depending on what it is used for. It must contain the SSCC number. The footer segment only contains the machine readable GS1-128 barcode.

The picture below depicts an example of a transport label. You will find in the middle segment, next to the SSCC number, the GTIN, the production date as well as the lot number. The bottom part contains two barcodes, the first one stands for the GTIN, production date and lot. The second stands for the SSCC number.

Example of a GS1 Label with SSCC

Incorporating the SSCCs on pallets

As the type and structure of the shipping unit can differ, using boxes or pallets for example, so can the incorporation of the SSCC labels. If the label needs to be put on a box whose dimensions are smaller than 1 meter, then you need to follow the instruction sbelow:

Example of a SSCC label on a box

The SSCC label must be present on at least two sides, the distance between the label and the bottom of the box needs to be at least 32 mm and 19mm from the right and left edges. In the logistic trade, boxes are mostly stacked on pallets, these can contain one sort of boxes or mixed boxes.

An unmixed pallet only contains goods which have the same article number, e.g. “gherkins in glass, 250g, GTIN 9001234567896”. The SSCC labels will need to be fitted on the pallet the same way as for the boxes, at least two of them on different sides.

Mixed pallets are pallets on which you will find goods with different article numbers. To allow them to be sorted, sandwich pallets will often be used. This type of stacking might remind one of a classic club sandwich. Tasty!

Mixed pallets are mostly used for direct store deliveries. Unmixed pallets and sandwich pallets are predominantly used for warehouse deliveries and in cross docking scenarios.

In a sandwich pallet, every single pallet will have its own SSCC label and the sandwich pallet itself will have a master SSCC label. The master label aggregates the SSCC labels from all the layers. The picture below illustrates this concept:

Example of an SSCC Label on a Sandwich Pallet

As you can see on the left side, each pallet layer has its own SSCC label (Layer SSCC Label). The sandwich pallet is wrapped in a plastic film, thus creating a new and unique shipping unit. The shipping unit as a whole has a Master SSCC label, as seen on the right side of the picture. When the goods arrive at their first unloading point, the warehouse employees will only scan the master SSCC label, since the plastic wrap often makes the scanning of the labels underneath impossible.

If the single pallets are isolated further down the processing line, the employees will then use the layer SSCC labels to clearly identify the layers.

Use of a SSCC in a DESADV

When DESADV messages are used to announce a delivery, the EANCOM Standard defines four different scenarios:

1 – No SSCC and no Shipping Structure

In this scenario only the article numbers and total quantities of the shipping are stated. There is no representation of the shipping structure and no SSCCs are being used. The shipping structure defines which boxes are on which pallets, how many pallets are being sent etc. This type of representation and its content correspond to a basic delivery note on paper.

2 – SSCC per Pallet without Shipping Structure

In this version article numbers and total quantities are given. The packages are also identified with the SSCCs. However, the shipping structure is not described.

3 – SSCC per Pallet with Shipping Structure

This option clearly describes the hierarchy of the shipping structure up to the content of the pallets. The DESADV will contain information about the article numbers and total quantity of the boxes per pallet. Furthermore it will contain the description of the hierarchy of the composition of the delivery (number of pallets, number of boxes per pallet, etc…). Each pallet will be clearly identified thanks to the SSCC. Sandwich pallets will have every layer also identified with their own SSCC.

4 – SSCC per Box and Pallet and with Shipping Structure

In this last option, the hierarchy of the shipping structure is described. Both pallets and boxes have SSCC numbers.

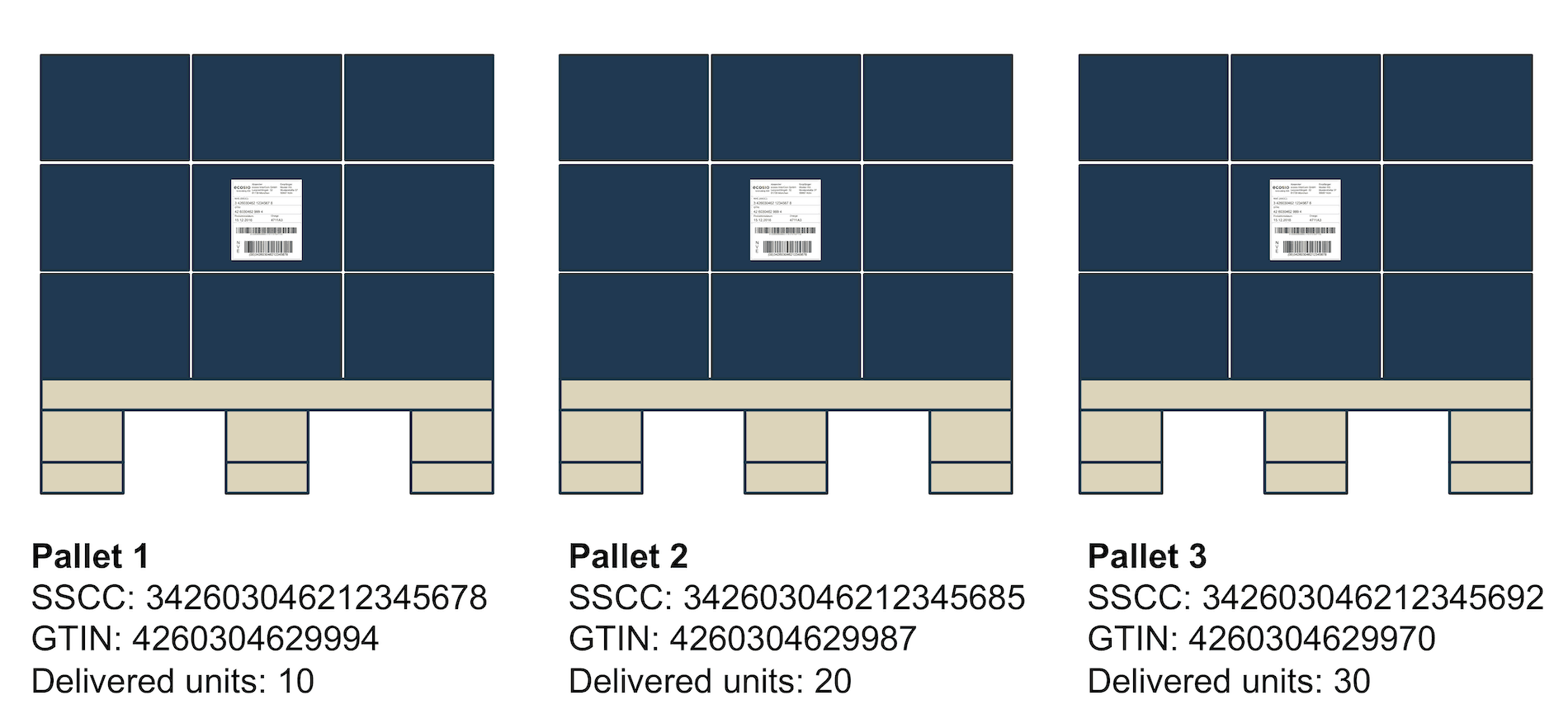

Example of an unmixed pallet

In the case of an unmixed pallet, the packing hierarchy can be described in two levels:

Level 1 = the whole shipping, which corresponds to three euro pallets in the example below.

Level 2 = per single pallet. This level dictates the representation of every single pallet, even if all pallets contain the same articles. The delivered units, usually boxes, are represented with GTINs. In the DESADV, you will find the distinction for the level hierarchy in the CPS segments.

Let us take a look at the three unmixed pallets below as an example. Each pallet has its own SSCC number. You will find different article types in each pallet, packed in individual boxes. The boxes have their own GTINs.

Example of three unmixed pallets

The resulting structure of the DESADV looks as follows (to make it clearer, we will only be showing the relevant CPS segments):

CPS+1'

PAC+3++201'

CPS+2+1'

PAC+1++201'

PCI+33E'

GIN+BJ+342603046212345678'

LIN+1++4260304629994:EN'

QTY+12:10:PCE'

CPS+3+1'

PAC+1++201'

PCI+33E'

GIN+BJ+342603046212345685'

LIN+1++4260304629987:EN'

QTY+12:20:PCE'

CPS+4+1'

PAC+1++201'

PCI+33E'

GIN+BJ+342603046212345692'

LIN+1++4260304629970:EN'

QTY+12:30:PCE'

The meaning of each segment is as follows:

CPS+1'

Corresponds to the highest order level.

PAC+3++201'

Number of packages in the whole delivery (3 euro pallets).

CPS+2+1'

Second hierarchy level (1st pallet). The 1 refers to the shipping. The 2 is the consecutive number of the hierarchy level.

PAC+1++201'

Number of packages in the current hierarchy level ( Pallet 1 = 1 euro pallet).

PCI+33E'

This shows the package is identified with an SSCC.

GIN+BJ+342603046212345678'

The SSCC number from pallet 1.

LIN+1++4260304629994:EN'

The GTIN of the delivered unit in pallet 1 (of the boxes).

CPS+3+1'

Second hierarchy level (2nd pallet). The 1 refers to the shipping. The 3 is the consecutive number of the hierarchy level. The other segments for pallets 2 and 3 are to be read in the same way.

Example of a sandwich pallet

In a sandwich pallet, the articles of the same type are stacked on each other. The single layers are separated by a euro pallet and have their own SSCC number. The whole pallet is then wrapped in plastic film and has its own master SSCC number. This number allows for the different layers underneath to be recognised during the unloading process.

The difference between unmixed and sandwich pallets is that the latter will have to have one more level in their hierarchy. Level 1 and 2 will be the same as for an unmixed pallet, however the master SSCC will be found on level 2. The delivered units are therefore represented in the third level.

Let us have a look at the sandwich pallet below with three levels.

Here is how the DESADV structure would look like:

CPS+1'

PAC+1++201'

CPS+2+1'

PAC+1++201'

MEA+PD+LAY+PCE:3’

PCI+33E'

GIN+BJ+342603046212345104'

CPS+3+2'

PAC+1++201'

PCI+33E'

GIN+BJ+342603046212345692'

LIN+1++4260304629970:EN'

QTY+12:30:PCE'

CPS+4+2'

PAC+1++201'

PCI+33E'

GIN+BJ+342603046212345685'

LIN+1++4260304629987:EN'

QTY+12:20:PCE'

CPS+5+2'

PAC+1++201'

PCI+33E'

GIN+BJ+342603046212345678'

LIN+1++4260304629994:EN'

QTY+12:10:PCE'

Here is what these segments mean:

CPS+1'

Stands for the first level (the actual shipping)

PAC+1++201'

Number of packaging in the whole shipping ( 1 euro pallet)

CPS+2+1'

Second level (the sandwich pallet)

PAC+1++201'

Number of packaging in the current level (1 euro pallet)

MEA+PD+LAY+PCE:3’

Number of layers in the sandwich pallet

PCI+33E'

Indicates a SSCC labeling is present

GIN+BJ+342603046212345104'

The SSCC number of the pallet (=Master SSCC)

CPS+3+2'

Third level for the description of the first layer. It refers to the pallet (with the “`2““)

PAC+1++201'

Number of packages (1 euro pallet)

PCI+33E'

Indicates a SSCC labeling is present

GIN+BJ+342603046212345692'

SSCC from the first layer

LIN+1++4260304629970:EN'

The GTIN from the delivered unit in the first layer

QTY+12:30:PCE'

The number of delivered units in the first layer

CPS+4+2'

Third level describing the second layer. The description for layer 2 and 3 is the same as for layer 1.

Benefits for all involved

Using DESADV messages with SSCC labels can be cumbersome at times, however the use of SSCCs has its advantages for the parties involved. It can help reduce the sending and picking times on the side of the supplier in the warehouse processing. The advanced notice of the delivery and the use of the SSCC allows the retailer to plan their logistics widely and optimise their workload and warehouse capacity.

As soon as the supplier delivers the goods, the unloading and storing can happen much quicker, reducing the time the trucks have to stay. The supplier then has more flexibility when booking time slots for the delivery. The retailer also benefits from the simplified processes when storing the goods. SSCCs can also guarantee transparency by complying with the legislation on products origins and tracing them back.

The automation of receiving goods also has benefits on the following processes, such as product recalls, confirmation of the goods reception etc. The use of DESADV with SSCC makes the suppliers competitive, as they can comply with the expectations of the retailers.

Should you wish to consult your crystal ball to see the future of DESADVs with SSCC in the retail industry, all you need to do is look at the the delivery processes in the automotive industry. The advanced notice of a delivery and the labelling are mandatory, so much so that it is a necessary pre-condition in establishing a partnership between a supplier and a buyer.

Do you have any questions?

You still have questions about DESADV and SSCC, or you need to implement those processes for one of your clients or suppliers? Feel free to contact us, we would love to help you!

Image credits

- An old fashioned grocery store: GNU Free Documentation License, Version 1.2, via Wikimedia Commons

- Club sandwich, Creative Commons CC0 1.0 Universal Public Domain Dedication