For modern businesses the visibility and accuracy of data is crucial. In particular, with supply chains increasingly relying on automated processes, data consistency is key. Even small inconsistencies in the information exchanged between B2B partners can cause frustrating and potentially expensive errors, such as incorrect fulfillment of orders or message failure.

The answer to these problems lies in ensuring your business has reliable master data. But what is this exactly, how can accurate it impact your B2B processes, and what does a good master data system look like? Let’s explore…

What is master data?

Master data, as the name suggests, is the most important data held by a business. Typically this data is information that is high level and non-transactional, and therefore likely to be more stable, used more frequently, and most useful for reporting and informing future strategy. While different industries and individual companies may treat different data elements as master data, common examples of master data elements include basic information such as the name of a supplier/customer and product reference numbers.

Given the nature of master data, this information is often used across multiple platforms and software programs in a business. To avoid inconsistencies and confusion, it is important that the exact same identifiers are used for master data elements – whatever these identifiers are (numbers, letters, words, codes etc.). Good master data management therefore involves ensuring that there is a single central record of certain data elements (e.g. supplier name), which data is pulled directly from when used in transactions and messages etc. This way, when information needs to be changed, all that is required to ensure that the new, correct data is used across the business is for the master data element to be updated.

The problems with having poor master data and processes

Although every supply chain business depends on the successful exchange of data to/from partners, many do not have reliable master data lists. This can be caused by a number of factors, such as the existence of multiple data lists that need to be consolidated (common after mergers and acquisitions), or simply a lack of prioritisation of data management by IT teams. Similarly, some companies may have well-maintained master data lists, but lack the necessary processes to ensure that data is used correctly.

Whatever the reason behind a company experiencing issues with master data, however, the resultant issues are the same. These fall into three main categories:

1) Errors

First and foremost, the most apparent issue relating to poor or inconsistent master data is the increased capacity for errors. An incorrect address, for example, can lead to delays and frustration on both ends of a transaction as messages/orders do not reach the intended recipient. Similarly, erroneous item prices and account numbers can cause huge repercussions for the company and individuals at fault.

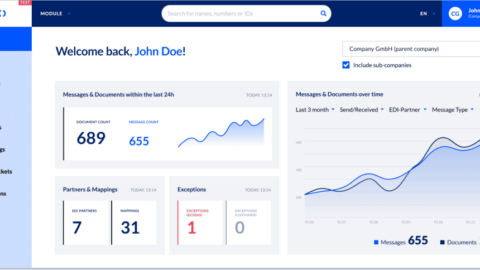

2) Reduced capacity for performance analysis

With poor data management, seemingly simple tasks, such as identifying which customers are most valuable to your business or which products are most popular, become difficult. Without the ability to pull reliable reports on B2B information and KPIs (key performance indicators), it becomes tricky to identify both how you are currently performing and what can be done to improve moving forward.

3) Inefficiency

With reliable data, data entry and data processing are fast and simple. Sadly this is not the case in businesses without good data processes. In businesses with messy data, automation is extremely difficult; information in individual transactions typically needs to be checked, interpreted and inputted manually if costly errors are to be avoided. Manual data processing is not a viable long term solution for growing businesses, however, as human errors are unavoidable – plus staffing costs will quickly eclipse the cost of investing in an automated system.

Master data: a crucial first step towards wider automation

Over recent decades automation has grown from being a “nice to have” to an essential part of modern supply chains. From internal system automation to the exchange of structured electronic messages between partners (known as electronic data interchange, or EDI), virtually every stage of the trading cycle can now be improved by intelligent technology. The pace of business today is such that manual processes are simply unable to compete in terms of efficiency and cost effectiveness

Without reliable master data it is difficult for any level of supply chain automation to be implemented. Think of your ideal, cost- and time-effective business processes as a house you want to build. In such a scenario your master data elements are the bricks. If they are inconsistent or poorly cast, this will have an impact on the stability of the whole structure.

As a result, for any supply business looking to move towards automation of any kind, taking the time to build a reliable master data list and accompanying processes is an important first step. Unfortunately, as building master data and conducting master data synchronisations can be time consuming, many businesses put these tasks off until they are absolutely necessary. When they then come to implement an EDI solution this leads to unnecessarily time-consuming migrations and customer onboardings.

Once I have sorted my master data – what next?

If you would like to find out more about what kind of automation it is possible once you have cleaned up your master data, why not read our article What is Electronic Data Interchange and What are the Benefits of EDI? If you would like to know more about what implementing an EDI system entails, you may also be interested in this article, where we explore this process in detail.

Alternatively, if you have any other questions regarding this topic or anything relating to B2B integration please do feel free to get in touch.