3M – beyond the Post It

Even if you have not heard about 3M in the past, it is quite likely that you stumbled upon one of their products in everyday life. One of their most famous products is, without doubt, the Post It note. In innovation classes, Post It notes are often taken as a famous example for a serendipity innovation. Originally in search for a super-strong adhesive, the chemist at 3M created a low-tack glue which allows for an easy attachment and detachment of the glued item. The rest is history.

Today 3M produces much more than just Post It notes. In order to allow for efficient management of its procurement and distribution processes, 3M makes heavy use of electronic data interchange (EDI). In the rest of the article we outline the most important facts in regard to EDI on the supplier’s side – that is, if your company delivers goods or services to 3M.

EDI with 3M

If you have been requested to start doing EDI with 3M, there are three important aspects to consider: document formats, exchange protocol and the onboarding process with 3M. We will further examine all three aspects in detail.

EDI document formats

On the supplier side 3M typically focuses on the following EDI document types:

- ORDERS (Purchase Order)

- ORDCHG (Purchase Order Change)

- ORDRSP (Purchase Order Response)

- DESADV (Despatch Advice)

- INVOIC (Invoice)

Thereby, they support the following EDI document formats:

- EDIFACT D96A

- ANSI ASC X12 version 4010

The exact format specifications may be retrieved as follows.

- Go to: https://www.3m.com

- Select your preferred Location/Language

- Select menu options > Suppliers > Source to Pay Transactions > Electronic Data Interchange

- Download the required document

Unless your ERP system is able to directly import and export the EDI formats mentioned above (which is unlikely), you have to employ a converter solution. The converter solution translates between the document format of your ERP system and the EDI format of 3M and vice versa. Usually converter solutions come either as an on-premise solution, or are provided by a service provider as a managed solution.

Of particular importance in regard to the document formats is the turnaround of information from 3M to your ERP and back to 3M. To be more precise – several identifiers have to be taken from the ORDERS message, which is received from 3M and must be returned in the documents which are being sent back to 3M (ORDRSP, DESADV and INVOIC). When using EDIFACT, the following turnaround principle applies.

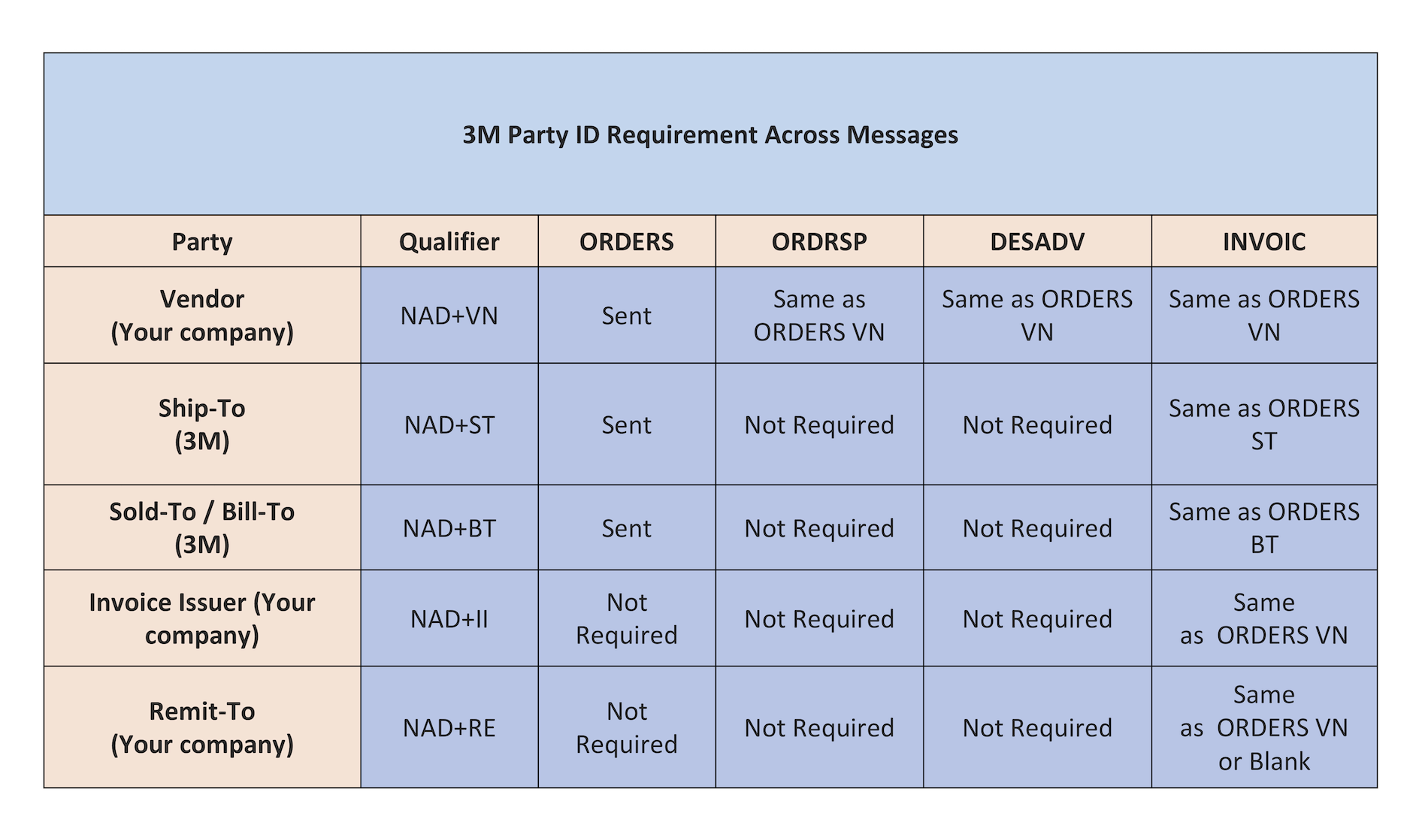

3M Party ID Requirement Across Messages

It is, for instance, essential, that the NAD+VN information from the ORDERS is correctly returned in the ORDRSP, DESADV and INVOIC message. The most complex document type is the INVOIC message. All NAD identifiers from the original ORDERS must be correctly returned in the INVOIC message.

Thus, it is imperative that the correct turnaround process is configured in the ERP system, ensuring that all information from the ORDERS is stored in the ERP and correctly returned when the INVOIC is exported.

When working for instance with an SAP ERP system, the correct configuration of the EDPAR table helps transfer the identifiers from the ORDERS through the ERP and back to the INVOIC document.

EDI exchange protocol

To allow for an exchange of EDI documents with 3M, an exchange channel using an EDI protocol must be set up. An EDI service provider like ecosio can take care of this connection for you and create a connection to 3M’s EDI service provider in order to exchange the required EDI messages. Exact details of the provider will be communicated to you by 3M during the course of the project.

3M along with their EDI service provider will set up two connections: a test connection and a productive connection. The test connection will be used during the onboarding phase to exchange documents with the test system of 3M.

The production connection is then used after the go live.

EDI onboarding process

The EDI team of 3M together with your own EDI service provider will assist you in setting up the EDI process to 3M.

First, master data has to be aligned to avoid disconnects relating to units of measurement and price multipliers. The necessary EDI document mappings should then be set up, after which 3M will provide you with EDI test orders via the test connection. You are then required to send back the necessary order response, despatch advice and invoice documents. Thereby, 3M’s onboarding team will execute various test cases, covering the different aspects of your business relationship to 3M, e.g., different types of deliveries.

After the test phase has been completed successfully, your EDI process will be put into production and your company will start to exchange EDI messages with 3M.

How ecosio can help

Ecosio is experienced in connecting suppliers to 3M and recently connected Mitsubishi Polyester to the conglomerate.

Our unique Integration Hub supports all secure EDI protocols and formats, meaning one connection to ecosio allows message trading with 3M (and other partners) in the correct format and over the correct protocol with minimum effort.

Unlike other providers, ecosio offers an integrated, managed solution which is embedded directly in the user’s ERP system as a native feature. As a result, important processes are built into the existing user interface, producing useful end-to-end message visibility.

Benefits at a glance

- All testing, mapping and routing achieved via a single connection to ecosio’s cloud-based EDI solution (our Integration Hub)

- No internal EDI knowledge needed

- Hassle-free partner onboarding

- Unparalleled end-to-end data visibility thanks to deep ERP integration

Any questions?

If you still have questions, feel free to contact us. We would love to help you!

SAP ERP and SAP S/4HANA are the trademarks or registered trademarks of SAP SE or its affiliates in Germany and in several other countries.