When looking at the benefits that Electronic Data Interchange (EDI) can bring to an organisation, investing in a reliable EDI solution seems like a no-brainer. No supply chain today that is still dependent on paper and email communication can be successful in the long term. EDI supply chains are, and have long been, the only futureproof option.

But EDI integration in modern ERP systems is a complicated process and one that requires significant expertise if a long-lasting solution is to be achieved. While there are many things that can go wrong when implementing/migrating to a new EDI solution, there are four main hurdles that must be overcome: standards, technology, processes and legal requirements…

Hurdle 1: Standards

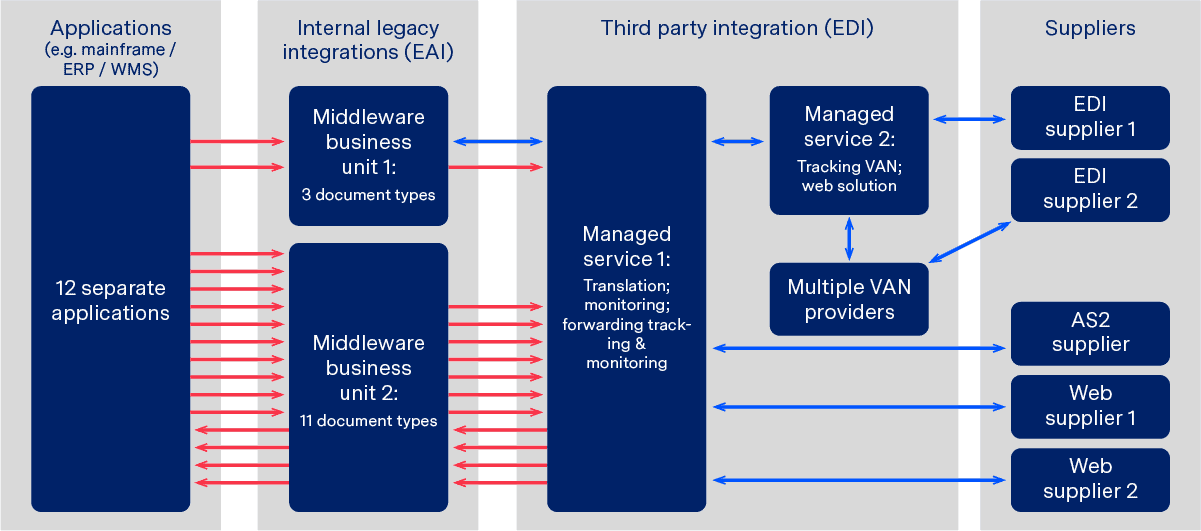

EDI document standards were created to make supply chain automation easier by providing a set structure for commonly used B2B documents. However, as EDI has evolved over the decades, more and more standards have been created to cater to increasingly specific requirements across different industries and geographical areas. The image below, for example, illustrates how the need for increasingly specific formats has led to the creation of a multitude of subsidiary standards under the umbrella of the EDIFACT core standard.

Faced with this ever-growing maze of standards and formats, businesses require the ability to send messages via various protocols and convert messages easily between multiple different formats. Given most businesses have only minimal in-house EDI expertise, it’s no surprise that the technical effort involved in automating the conversion between message formats is one of the most common hurdles on the path to EDI supply chain success.

Hurdle 2: Technology

Thanks to recent innovations such as APIs and common import and export interface standards of ERP systems (e.g. based on XML or JSON), businesses have ostensibly never been better positioned to achieve widespread supply chain automation.

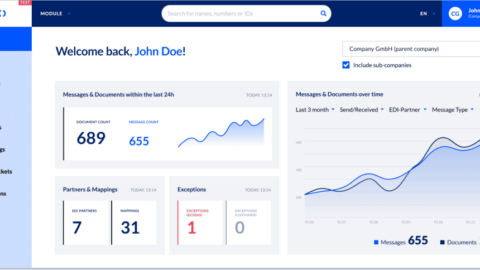

Unfortunately, however, many businesses are hampered by extremely complicated legacy IT landscapes and are therefore unable to experience the benefits of streamlined EDI. As illustrated by the diagram below (which shows the genuine IT landscape of a large retailer pre-upgrade), often legacy systems include several separate information silos and connections to multiple service providers. With no central governance and such a wealth of areas where errors could occur, internal teams are often scared to touch anything in case they disrupt or break mission critical processes.

Similarly, some ERP systems are so basic that they are unable to exchange structured files. This capability must therefore be implemented before EDI functionality can be integrated.

Hurdle 3: Processes

Whilst selecting middleware that can handle your business’s technical requirements is obviously important, even more important is establishing the right processes, as without these lasting success is impossible. Though integration admittedly requires expert knowledge, the technical aspect of integration is often the easiest part, with Gartner noting that:

“Only 5% of the interface is a function of the middleware choice. The remaining 95% is a function of application semantics.”

Successful EDI supply chain automation relies on efficient processes. For example, monitoring and support processes are essential if errors are to be identified and resolved before they impact partners.

Generally, successful EDI processes rely on the following key factors:

- Deep application and domain know-how of the business involved

- Technical capabilities

- Available resources

- Project management skills

- Project management support (e.g. onboarding tools)

Hurdle 4: Legal requirements

In an effort to save costs and gain more transparency regarding B2G invoices, many governments have introduced legislation dictating how companies should format and transmit structured electronic invoices (a subject we cover in detail in our e-invoicing white paper). Since April 2020, the majority of European government bodies have been required to accept electronic invoices. Moreover, many countries are seeking to make all B2B and B2G e-invoicing mandatory in an attempt to reduce the so-called VAT gap between expected and collected VAT revenues.

Given the geographic reach of most EDI supply chains and the pace at which e-invoicing legislation in particular is being created and amended, staying on top of regulations is no easy task. Non-compliance with regulations is not an option, however, as it can bring large fines.

If you want to stay on top of e-invoicing regulations, why not sign up to our E-invoicing Updates Newsletter? By doing so you’ll get all the most important e-invoicing updates and helpful e-invoicing assets direct to your inbox every two months!

Want more information on how to overcome these hurdles?

This article is a snippet from our white paper Unlocking the Secrets to Successful EDI Integration. In this paper we explore the development of ERP systems, what makes an EDI supply chain resilient, how to avoid common integration headaches, the benefits of full EDI integration and how to ensure your integration project is a success.

Download your copy of “Unlocking the Secrets to EDI / ERP Integration Success” and find out how you can implement (and benefit from) a solution that is able to overcome all four of the hurdles discussed in this article, simply fill in your details.

Alternatively, if you have any questions about supply chain automation or anything else EDI related, feel free to get in touch! We are always happy to help!