What is Web EDI?

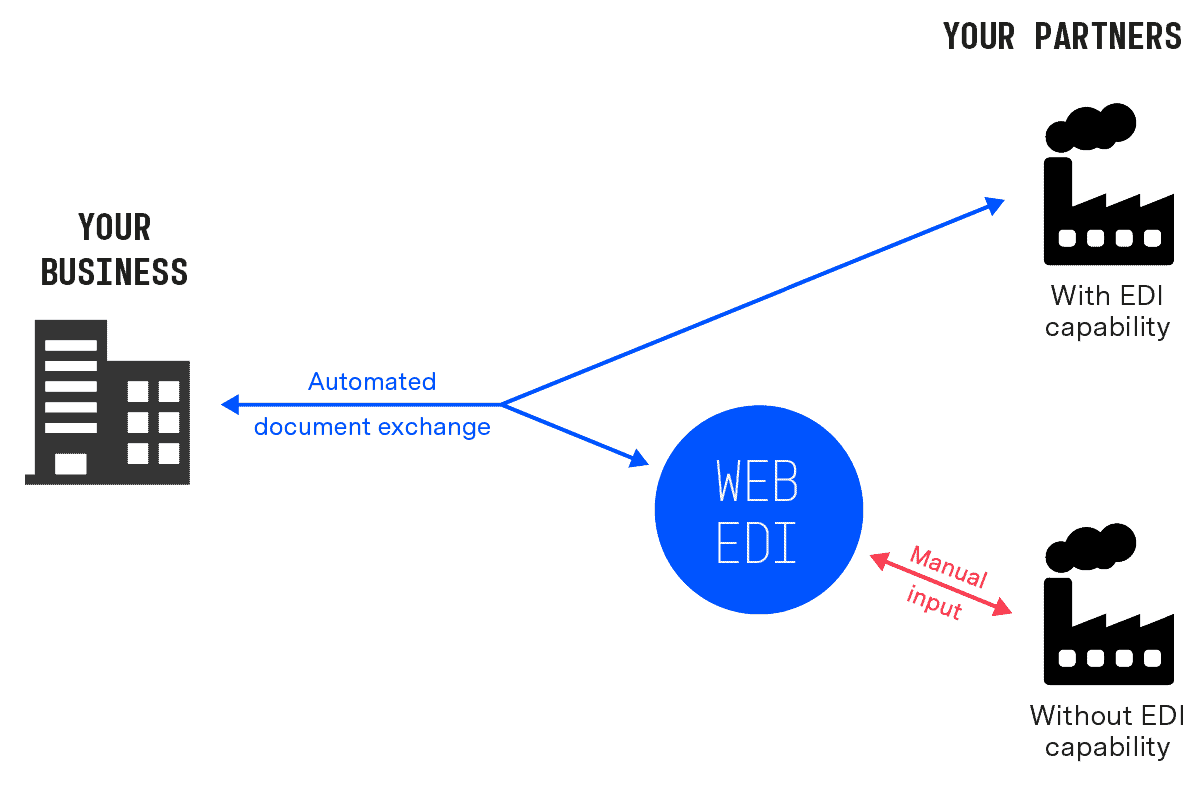

As we explain in our video on this topic, Web EDI is a tool for connecting to suppliers that lack the infrastructure to conduct EDI in the traditional manner. In addition to enabling your suppliers to decrypt your EDI messages to them, it allows partners to add data relating to orders and invoices etc., converts them into structured electronic messages, and transmits them directly into your ERP system.

This way businesses are able to extend automation across as much of their supply chain as possible. For your partners it allows simple transmission of EDI documents via a web portal. Meanwhile deep integration with your ERP system ensures that, for you, message exchange via Web EDI looks no different to that via classic EDI.

Your benefits

- A more streamlined partner network

- Cost and time savings through increased automation

- Less pressure on in-house teams

- ecosio also offers 24/7 platform monitoring and provides updates free of charge

Supplier benefits

- Access to real-time purchase order information and purchase order changes (in good systems all order changes can be merged automatically)

- Semi-automated creation of key B2B documents

- The ability to trade with larger partners

Why is Web EDI Needed?

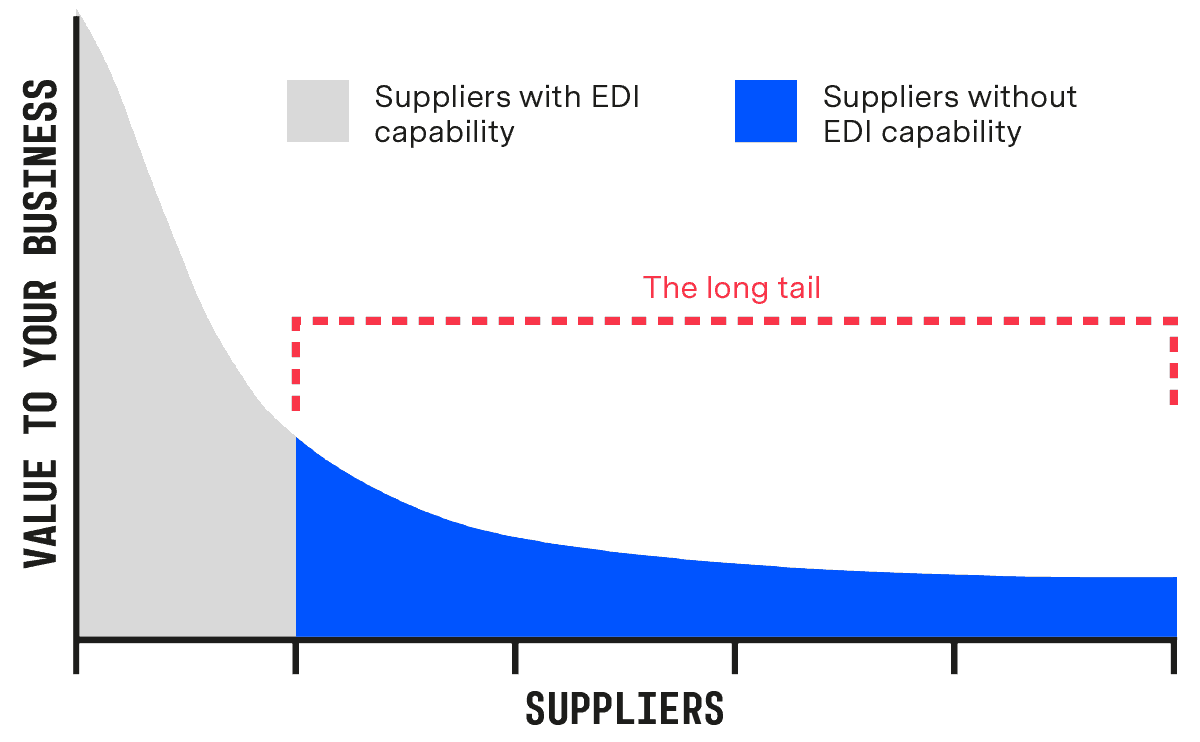

Generally speaking, a supply chain business’s suppliers can be divided into two distinct groups:

1) Larger suppliers

- These suppliers are able to do classic EDI

- In order to trade automated messages with large suppliers prospective EDI partners must send them a message implementation guideline (MIG) according to their own specifications (in rare cases very large suppliers may be the ones dictating the standards)

Smaller suppliers

- Known as the “long tail”

- These suppliers do not have the ability to conduct EDI

- They are only able to trade automated messages if their partner provides access to a Web EDI portal

Although the majority of messages exchanged may be with larger suppliers, when added together, smaller suppliers often constitute a substantial proportion of a business’s partner network. Communication with smaller partners also typically requires a huge amount of time and effort from internal teams to ensure everything is processed correctly.

An efficient EDI solution should aim for total supply chain communication and therefore must cater for both types of supplier. As Web EDI offers the only way to achieve automated exchange of structured documents with partners lacking EDI capability, it is an essential part of a successful EDI solution.

How a Web EDI system works

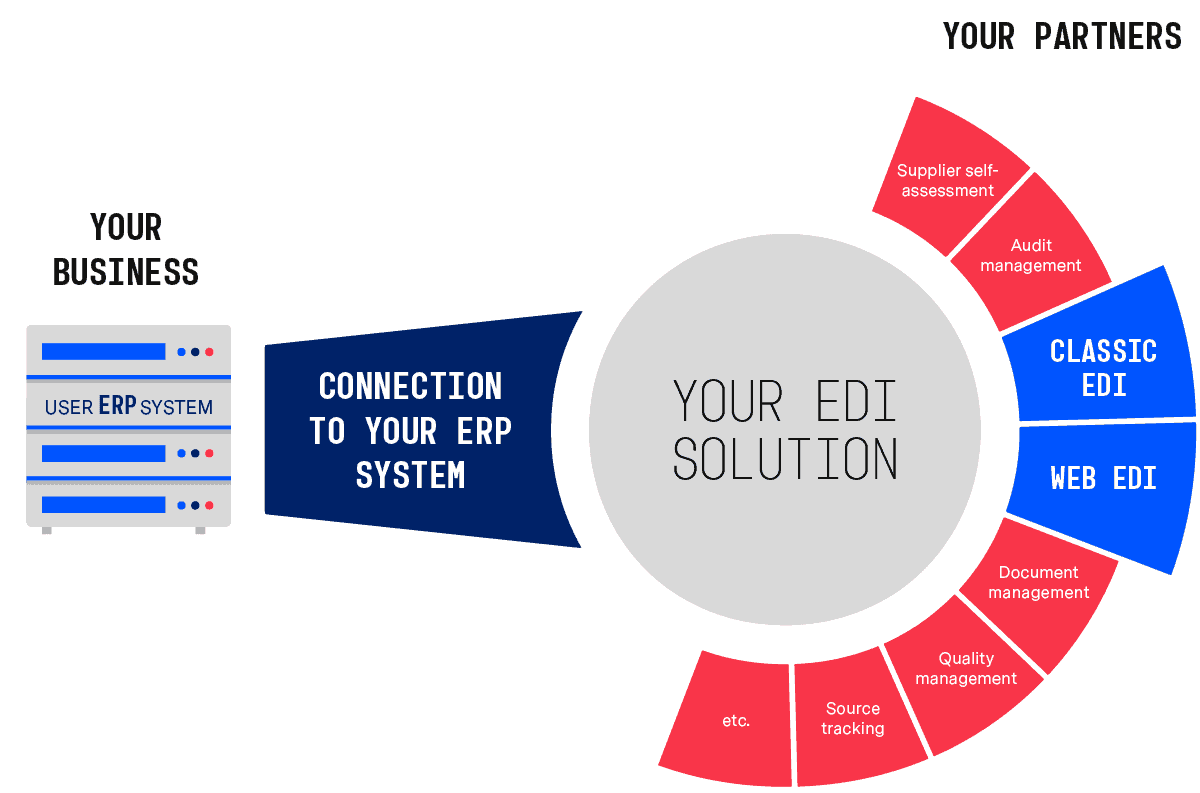

The diagram below shows how Web EDI fits into a wider B2B integration strategy. Significantly, with ecosio, both classic EDI and Web EDI connections can be established via a single direct connection between your ERP system and ecosio’s Integration Hub. As a result, full end-to-end message visibility is possible regardless of whether your partner has EDI capability or not.

From your perspective

Once smaller partners have been provided with access to your Web EDI portal, as far as your ERP system is concerned there is no difference between the messages received via Web EDI and those received from larger partners via traditional EDI. All B2B message exchange is automated, with all incoming messages arriving directly into your ERP and all outgoing messages similarly sent directly from your ERP. To see what a Web EDI system actually looks like, see our article on this here.

From your supplier’s perspective

Once your Web EDI platform has been created your suppliers will be provided with a login to your own tailored portal. Within this portal access rights and alerts can be set as desired.

Incoming messages: The supplier is informed by email when a new message arrives, meaning none are missed. Structured data is presented in a human readable format

and can be downloaded as PDF.

Outgoing messages: Can be semi-automatically created with pre-populated information, based on incoming messages (e.g. turnaround process from order to order response)

Below is a step-by-step example of a typical interaction of a partner and their Web EDI portal:

- They receive a notification that a purchase order has been received

- They log on to view the purchase order (with a deep link in the email)

- It can be downloaded as a PDF and printed

- A purchase order response is generated

- A dispatch advice is generated

- An invoice is generated

- Once checked, these documents can be sent with a single click

Want more information?

This article is a snippet from our white paper “Can Web EDI Really Transform My Supply Chain?”. In this white paper we also explore the challenges of Web EDI systems, how partners are connected, what makes a good system, how B2B integration can be expanded beyond core processes, and provide examples of what a Web EDI system looks like in practice.

To download your copy for free, simply click here and submit your details.

Alternatively, if you have any questions about your particular situation or anything else EDI related, please do not hesitate to get in touch! We are always happy to help however we can.