🔍 TL;DR summary

- Suppliers are categorised as Tier 1, Tier 2, Tier 3, Tier-n based on their distance from the OEM, reflecting the sub-supplier structure

- In the automotive industry, OEMs source modules from specialist suppliers, who assemble components from other suppliers, with individual parts supplied on the third tier

- Close links between OEMs and tier suppliers require fast and effective communication of required quantities to ensure the supply of modules, components and parts, particularly in just-in-time and just-in-sequence processes, supported by electronic data interchange

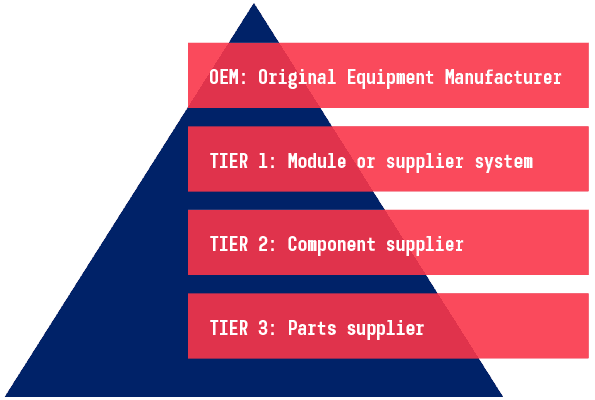

Structure of a supply pyramid

A supply pyramid describes the structure of a supply chain with the end product producer at the top. The end product producer is referred to as an OEM, which stands for Original Equipment Manufacturer. The suppliers of modules and systems are directly underneath the OEM. These suppliers are supplied by component suppliers who in turn buy their goods from parts suppliers.

Suppliers are referred to as Tier 1, Tier 2, Tier 3, Tier-n suppliers, depending on their distance from the OEM. This reflects the sub-supplier structure.

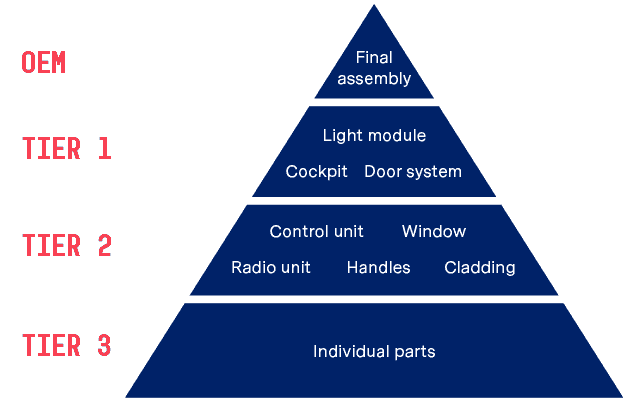

Tier supplier structure visualised – an example from the automotive industry

The automotive industry is characterized by complex and closely interlocked logistics chains. Instead of producing all their components in-house, automotive manufacturers procure the individual modules from specialist suppliers. These suppliers will in turn assemble components supplied by specialised component suppliers. The suppliers of individual parts are found on the third tier.

These boundaries are not always so clearly defined. A supplier may thus be both Tier 1 and Tier 2 – for example a business might deliver antenna modules to both OEMs and Tier 1 suppliers.

The following diagram illustrates an example of an automobile supply chain:

Supply pyramid in the automotive industry

Challenges along the supply chain

Close links between OEMs and their individual tier suppliers pose special challenges to smooth process operation. The horizontal integration of many different suppliers and their own suppliers will, for instance, demand that required quantities are communicated fast and effectively if the supply of modules, components and individual parts is to be ensured. This is a critical factor in success especially with just-in-time and just-in-sequence processes. Electronic data interchange is used to ensure communication, whilst the concepts of delivery schedule and just-in-time deliveries may for instance be deployed. Standardisation organizations such as ODETTE and VDA have already developed many useful standards to allow efficient operation of automobile supply processes.

Apart from logistics messages such as delivery schedule, despatch advice, etc., continuous digital engineering is essential. This will, for instance, include the exchange of construction data such as CAD (Computer-aided design) drawings and the like.

Any questions?

If you have questions about logistics in the automotive industry or would like to learn more about implementing an EDI based process please contact us – we look forward to hearing from you!

You can also find more useful information on this and other relevant topics in our extensive resource centre and blog.