Eine optimale B2B-Kommunikation ist für die meisten Unternehmen heutzutage unverzichtbar. Automatisierung ist dabei für viele Betriebe das Mittel der Wahl, um einen noch besseren Datenaustausch mit Kunden realisieren zu können. Vor allem die EDI-Schnittstelle spielt in diesem Zusammenhang eine große Rolle, kann sie die Datentransparenz doch über alle EDI-Kanäle hinweg verbessern. Vor allem für zukunftsorientierte Zulieferer ist ein effizientes und wartungsarmes EDI-System das Ziel. Denn sie wissen: Die einfache und verlässliche Überwachung von Nachrichten ist entscheidend. Weniger bekannt ist jedoch der Einfluss der sogenannten „letzten Meile“ (also der Verbindungsmethode des ERP-Systems mit dem jeweils gewählten Anbieter) auf die Effizienz der EDI-Lösung.

Welche Vorteile in diesem Zusammenhang die EDI-Integration hat, welche Rolle die EDI-Schnittstelle spielt und wie diese Ihre EDI-Landschaft verbessern kann, erfahren Sie in diesem Artikel.

Bekannte EDI-Schnittstellen und ihre Nachteile

Bevor es gleich um die Vorteile der Verwendung einer EDI-Schnittstellen für die „letzte Meile“ und um Ihr ERP-System geht, lohnt sich zunächst ein Blick auf die Einschränkungen, die gängige Methoden anderer EDI-Anbieter mit sich bringen. Dazu gehören unter anderem:

- AS2

- OFTP2

- SFTP/FTPS

- weitere (wie z. B. RFC für SAP®-Systeme)

Denn auch wenn es Unterschiede zwischen diesen unterschiedlichen Arten der EDI-Schnittstelle gibt, weisen sie dennoch alle die folgenden Gemeinsamkeiten auf:

- Kein expliziter Verbindlichkeitsnachweis: Bei einigen Protokollen wie SFTP oder FTPS können Empfänger keine standardmäßigen Bestätigungen an den Absender zurücksenden. Der Absender bekommt also keinen expliziten Nachweis darüber, ob der Empfänger die gesendete Datei tatsächlich erhalten hat. Der Nachweis erfolgt nur implizit durch die Tatsache, dass der Empfänger die Nachricht gelesen und empfangen hat und sie dann entweder verschoben oder gelöscht hat. Während die Übertragung von Nachrichten in den meisten Fällen funktioniert, ist die Nachverfolgung eines Nachrichtenaustauschs schwieriger – insbesondere, wenn ein Fehler passiert ist. Mit modernen Protokollen wie AS2 oder AS4 und einer optimal angepassten EDI-Schnittstelle lässt sich dieses Problem beheben.

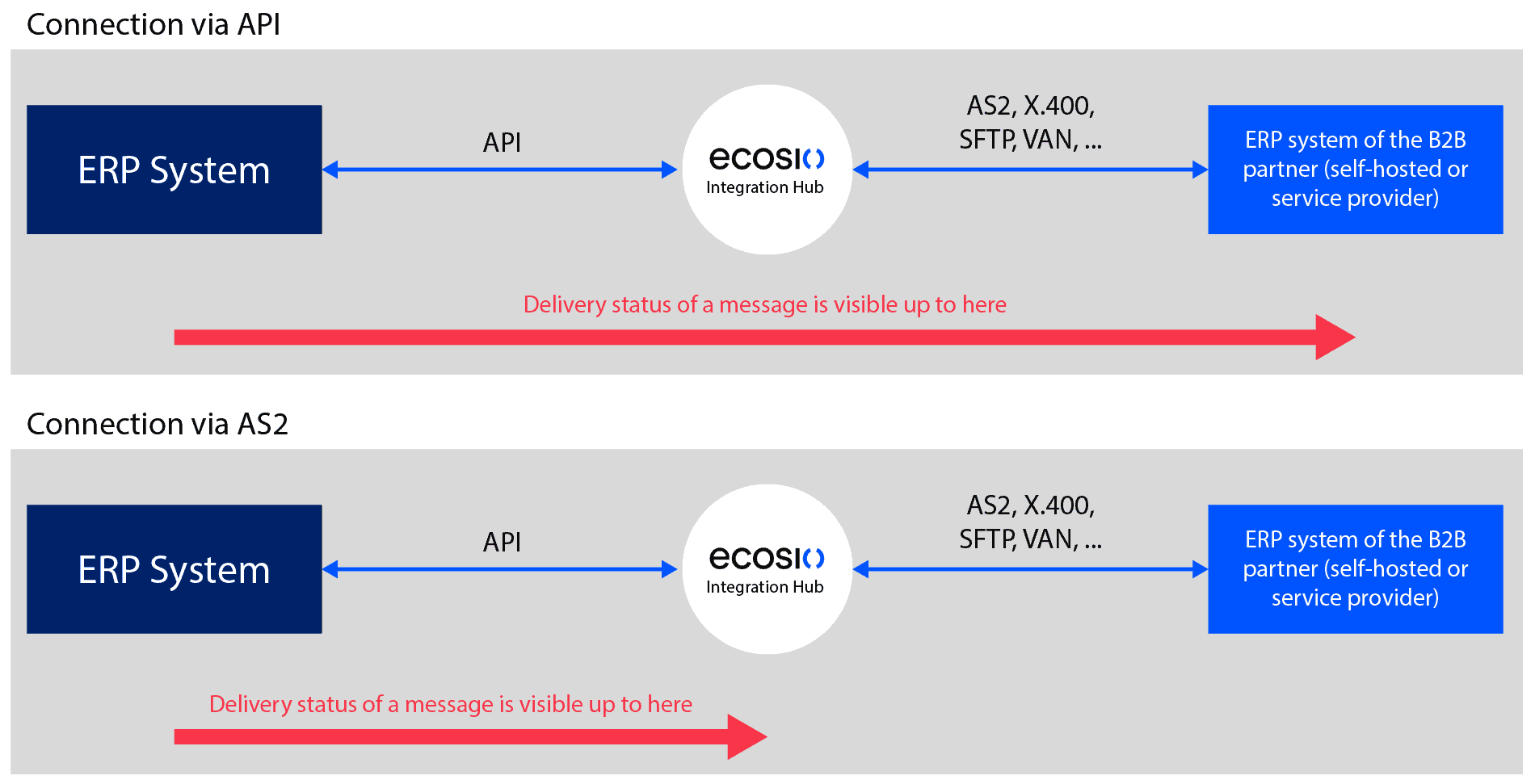

- Keine vollständige Rückverfolgbarkeit der Prozesse: Wird eine Nachricht versendet, lässt sich ihr Zustellungsstatus nur bis zum nächsten Netzwerk, jedoch nicht darüber hinaus verfolgen. Im Falle ausgehender Nachrichten bedeutet dies, dass das ERP-System nachvollziehen kann, ob die Nachricht vom EDI-Dienstleister empfangen wurde. Ob sie aber auch beim Endempfänger angekommen ist, lässt sich nicht prüfen – eine Herausforderung, die selbst moderne Protokolle wie AS2 oder AS4 nicht lösen können.

Es gibt jedoch eine Verbindungsmethode für die „letzte Meile“, bei der diese Probleme nicht auftreten: die Verwendung von Application Programming Interface (kurz API).

API als EDI-Schnittstelle – was ist das genau?

Einfach erklärt, ist eine API eine Sammlung von Regeln und Protokollen, die festlegt, wie die verschiedenen Anwendungskomponenten durch die Definition von Austauschformaten, Austauschprotokollen, Sicherheitsanforderungen und weiteren zusammenwirken sollen.

Wie unterscheiden sich API-Schnittstellen von anderen?

Der Unterschied zwischen den eingangs oben genannten EDI-Verbindungen und API-Verbindungen liegt im Schnittstellenmanagement. Denn der Zugriff auf die EDI-Nachrichtendaten sowie auf den mit einer bestimmten EDI-Nachricht verbundenen Status erfolgt direkt über eine spezielle EDI-Schnittstelle. Als Nutzer haben Sie davon eine Menge Vorteile. So verhindert eine verlässliche EDI-Schnittstelle den Verlust von Metadaten, weil sich spezifische Informationen über die bestehende Benutzeroberfläche Ihres ERP-Systems in Echtzeit anzeigen lassen. Das kann zum Beispiel der Hinweis sein, ob eine Bestellung oder Rechnung beim EDI-Dienstleister angekommen ist, oder aber die Information, ob der endgültige Empfänger eine Nachricht erhalten hat. Diese Echtzeitabfrage verbessert die Effizienz Ihrer Lieferketten signifikant und minimiert zudem die Gefahr von Verwechslungen und Fehlern.

Und tritt doch einmal ein Fehler auf, können Sie als Nutzer schnell feststellen, an welcher Stelle dieser passiert ist und wie er sich zügig beheben lässt – dank der umfassenden Datentransparenz, die API-Schnittstellen bieten.

Welche klaren Vorteile API-Schnittstellen haben, zeigt Ihnen auch das folgende Beispiel: Stellen Sie sich vor, Sie warten auf die Antwort eines Lieferanten zu einer Bestellung, die Sie abgeschickt haben. Bei anderen Verbindungsmethoden können Sie wahrscheinlich nur feststellen, dass Ihre Nachricht korrekt gesendet wurde und der Adressat sie vermutlich erhalten hat. Arbeiten Sie hingegen mit EDI via API-Schnittstelle, können Sie direkt feststellen, wenn die Bestellung nicht eingegangen ist, und sofort sehen, woran die fehlerhafte Übermittlung gelegen hat. So haben Sie die Chance, die Bestellung direkt zu überprüfen, gegebenenfalls zu korrigieren und erneut zu senden.

Klicken Sie auf das Bild, um es zu vergrößern

EDI mit der Lösung von ecosio über eine API-Schnittstelle zu managen, bietet Ihnen zudem die Möglichkeit, eine Volltextsuche in Ihrem ERP-System durchzuführen. Damit lassen sich Dokumente wesentlich schneller finden, weil Sie sämtliche in einer Nachricht enthaltenen Kennzeichnungen (z. B. Artikelnummern, Metainformationen, AS2-Nachrichten-IDs oder OFTP2-Übertragungs-IDs) für die Suche verwenden können. Der direkte Zugriff auf die Daten in Ihrem ERP-System hilft außerdem, interne Arbeitsabläufe effizienter zu gestalten, da die Mitarbeiter aus den einzelnen Abteilungen selbst nach Informationen schauen können und nicht den Umweg über die IT-Abteilung gehen müssen.

Sie möchten mehr Informationen über die Nutzung einer API- bzw. EDI-Schnittstelle sowie zur Optimierung Ihrer EDI-Landschaft erhalten?

Dann werfen Sie einen Blick in den umfangreichen Medienpool von ecosio – wir bieten Ihnen zahlreiche Infos in unserem Blog sowie Infografiken und detailliertes Wissen in White Papers und Webinaren. Direkt in die Praxis geht es in unseren Case Studies, die Ihnen einen hilfreichen Überblick über aktuelle EDI-Projekte bieten.

Kontaktieren Sie uns

Wenn Sie mehr über EDI as a Service von ecosio erfahren möchten, kontaktieren Sie uns unverbindlich – wir beantworten gerne alle Fragen.