VDA standards

VDA standards are maintained by the German Association of the Automotive Industry and represent one of the important families of standards used by that industry. VDA is the acronym of Verband der deutschen Automobilindustrie.

Standard definitions are given for a variety of applications, referring not only to the structure of electronic documents, but also specifying, for instance, labels and shipping documentation.

VDA 4905 delivery call-off

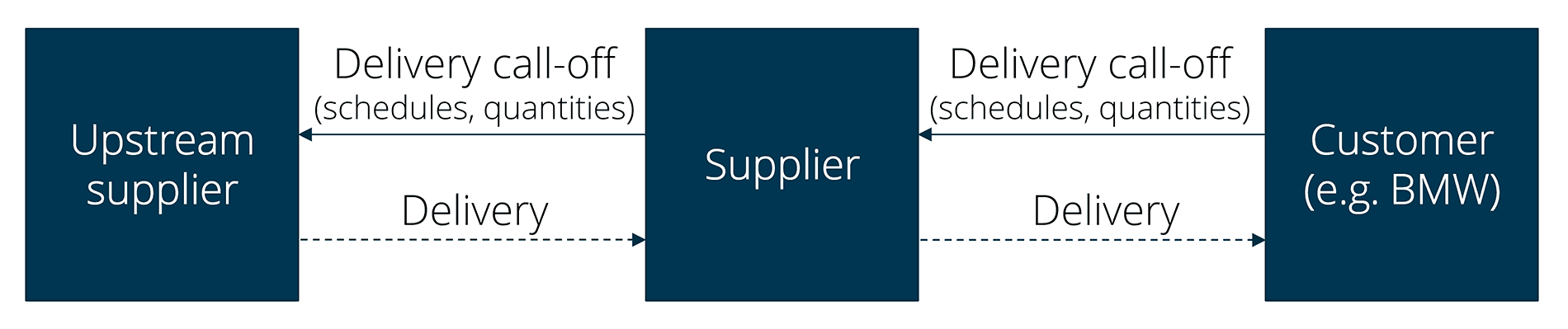

Delivery call-offs represent a key means of communication in the automotive industry, since tightly linked processes involving customers, suppliers, and upstream suppliers demand that changing supply chain dates and requirements must continuously be communicated “back up the chain”.

The principle is illustrated in the diagram below.

VDA 4905 delivery call-off principle

A new delivery call-off will fully override the previous delivery call-offs. Current requirements can therefore always be communicated back to the previous link in the logistics chain and up-to-date requirements are availabe to all business partners involved.

Learn how to resolve the key issues facing IT decision makers today

VDA 4905 delivery call-off structure

Similar to many other VDA standards, VDA 4905 delivery call-offs have a fixed dataset length of 128 characters. Adding a line break after every dataset will produce a sequence of rows. Each row starts with a three-character record type.

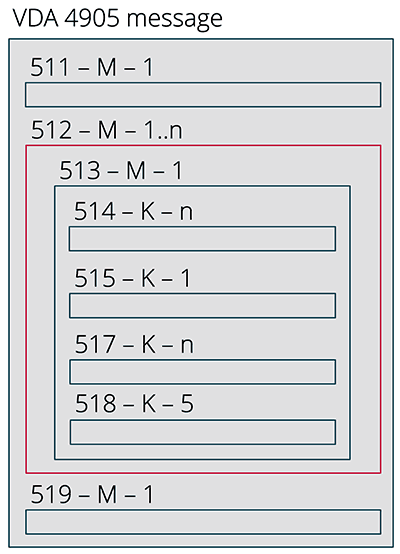

The diagram below illustrates the structure of a VDA 4905 message. The first three digits define the record type. M means, that the dataset is mandatory. K means, that the dataset is optional. M derives from the German muss, meaning must. K derives from the German kann, meaning can.

The last character indicates how often the dataset is allowed to be repeated, where n stands for as often as needed and 1..n for at least 1 to n times.

Structure of a VDA 4905 delivery call-off

The nested structure also indicates datasets, that can be repeated after a first dataset. The diagram shows, that transmission of delivery call-off data starts with record type 511 and will always end with record type 519.

A transmission must always contain record type 512 with the corresponding subordinate record types for every sorting parameter combination. In the VDA context, the sorting parameter combination includes the following parameters:

- Customer factory

- Customer material number

- Order number

- Unloading point

If, for instance, material number number a and number b and customer factory factory x and factory y are given and a call-off is required for both material numbers and both factories, the result will be as follows:

- 1 x 511

- 1 x 512 plus sub-record types (

material number ainfactory x) - 1 x 512 plus sub-record types (

material number ainfactory y) - 1 x 512 plus sub-record types (

material number binfactory x) - 1 x 512 plus sub-record types (

material number binfactory y) - 1 x 519

Differences compared to EDIFACT

The VDA standard has several special features compared to EDIFACT, which we briefly discuss below.

Sequential numbering

EDIFACT file transmissions are clearly identified by interchange references (provided in the UNB segment). Interchange references are issued by the sender and are numbered sequentially ascending. Using the interchange reference an EDIFACT transmission is easy to trace. In addition the message creation date and time in the UNB segment help with correctly identifying a transmission. Thus, wrong messages may, for instance, be traced and re-transmitted without a problem.

VDA has a different approach. A new transmission number and an old transmission number are transmitted for each transmission. New and old transmission numbers are unique references for the current and previous transmissions, respectively. No sequential numbering of the transmitted numbers is therefore required. Transmissions may furthermore be numbered differently, for instance in accordance with technical areas (e.g., orders for regular products as opposed to orders for spare parts).

Customer and supplier identification

It is customary in the trade that parties interchanging data (supplier, customer, invoice recipient, place of delivery, etc.) are identified by Global Location Numbers – GLN.

The automotive sector instead uses numbers that were exchanged bilaterally in advance. These may, for instance, include customer number, supplier number, customer’s factory number and unloading point.

Product identification

It is also customary in the trade that exchanged products are identified by a Global Trade Identification Number (GTIN). The GTIN is a number the producer assigns to his products. A consumer will recognise the GTIN as the number under the bar code, which can be found on almost all products in a supermarket shelf.

The automotive sector generally uses material numbers instead of GTINs. The supplier maintains his own list of individual customer material numbers, enabling him to assign them to his internal material numbers.

Cumulative quantity received

The cumulative quantity received comprises all negative or positive deliveries recorded by the customer, from a specific point in time. The quantity in transit will be the difference between cumulative delivery quantity by the supplier and cumulative quantity received at the customer.

The customer may also reset the cumulative quantity to 0 by sending a reset date in a delivery call-off. This date will then apply to all the parts of the supplier. Thus, the first call-off transmission after the reset shall contain all parts of the supplier relevant to the specific customer, allowing to start a new sequence.

Record type version numbers

Within the framework of VDA messaging (including VDA 4905) it is possible to assign version numbers to individual record types. EDIFACT does not provide for such version control on the record type level –- the only comparison would be EDIFACT directory version control -– e.g. EDIFACT EANCOM D96A vs. EDIFACT EANCOM D01B.

A common standard for all?

“The entire automotive industry relies on the VDA standard. Good news for all suppliers –- all companies in the automotive industry will be able to receive delivery call-offs using the same standard.”

Not quite, unfortunately…

Similar to EDIFACT, where the global EDIFACT standard (used in its pure form only by a few) has many subsets that are specific to certain industries and companies, the VDA also has versions that are specific to some companies.

This means, for instance, that German OEMs may have slightly different requirements under the VDA standard, that upstream suppliers will need to take into account.

More questions about VDA?

More questions on the topic of delivery call-off or other VDA standards? Please do contact us or use our chat — we’re more than happy to help!